Ultra Open Design Engineering

Sine Lite technology features ultra-open design engineered for wash down all stainless-steel construction

Ultimate Scaling Controlled Accuracy

Sine Lite technology offers the industry ultimate flow-meter monitoring scaling controlled accuracy.

Ultimate Bun Make-Up Systems

Sine Lite technology provides ultimate scaling controlled accuracy consistency and quality to your products

Consistency and Sustainability

Sine Lite technology provides consistency in quality of your products

The Industries We Serve

SINE LITE produces high-end manufacturing technology and services

that is a perfect complement to today’s high-tech industries.

Food Industry

Sine Lite caters to the Bakery Industry with the Ultimate most innovative Bread and Bun-Rolls Make-Up Systems.

Transportation Industry

Currently under development, research, and testing. We will be providing further updates related to this industry.

Technology Industry

The automated systems developed by Sine Lite use innovative technology and design combined with years of industry experience.

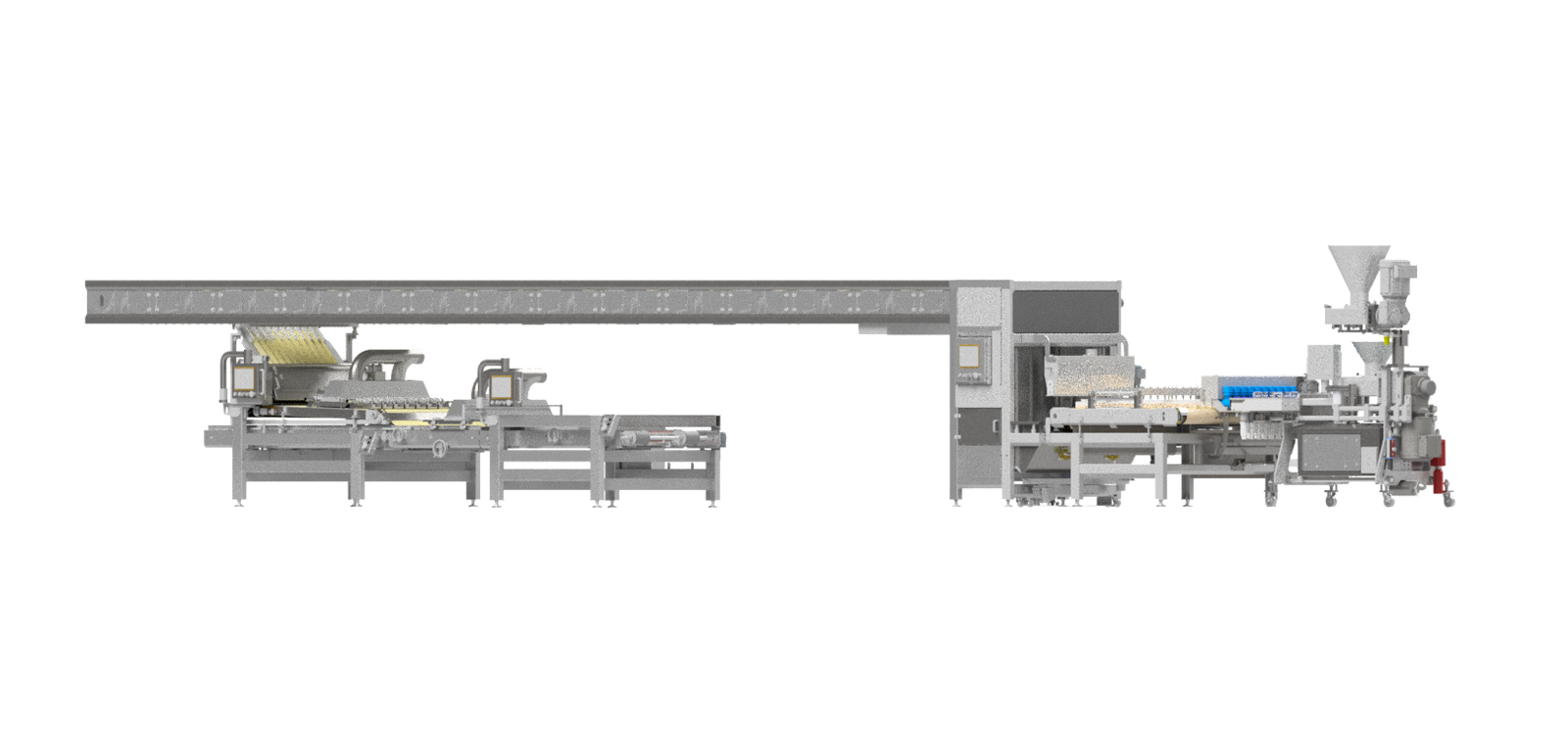

Ultimate High Speed Bread and Bun Makeup Systems

We provide three series of ultimate high speed bun makeup systems with integrated + FLOW METER technology listed below.

Ultimate High Performance Complete Industrial Bakery Bread and Bun Make-Up Intelligent Bakery Equipment Systems for High-Speed and maximize the Quality of your Bakery Products

SINE LITE’S Manufacturing of industrial bakery equipment, requires a vast knowledge of processes and fundamental concepts.

SINE LITE’S introduces our New FLOW-METER monitoring and control technology for scaling output accuracy of our Bread and Bun Dough Dividers designs seamless to integrated with our complete automated Make-Up Systems, Sine Lite’s high quality equipment sets the bakery industry’s new ultimate standards on intelligent baking solutions, for performance, scalability in real time, most of all maximize the sustainability, quality, and consistency of your bakery products.

SINE LITE’S Industrial bakery equipment recognized for hygienic, quality and real innovations.

- High Speed, up to and over 150 cuts per minute.

- Flow-Meter scaling Volume/weight monitoring and control accuracy, gearbox-servo motors driven.

- Hygienic ultra open dividers sanitary designs, for easy access to product zones.

- Visually inspect-able product path design, for deep cleanning.

- Tool-less design reduces cleaning time.

- Ultra-Open design lower sanitation and maintenance cost.

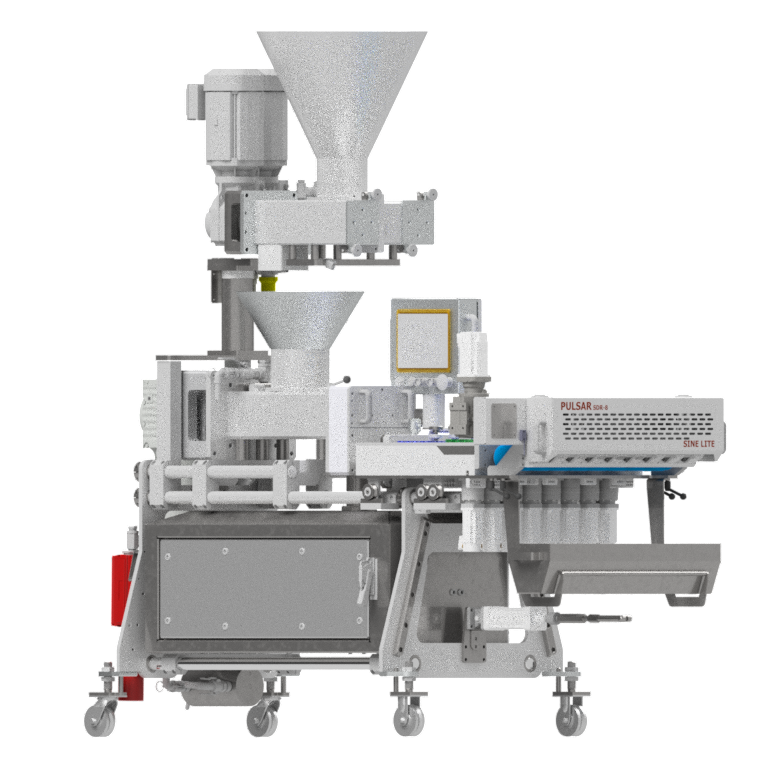

PULSAR DOUGH DIVIDERS

MS-SDR-10 PULSAR

Div. + Do-E6

The Impossible Ultimate MS-SDR-10 PULSAR Multi Servo Motor, Sine-Disk-Rotor + Flow-Meter monitoring and control in a close-loop in real-time Self-adjusting Volumetric-Mass/flow Controlled System practically eliminates human intervention.

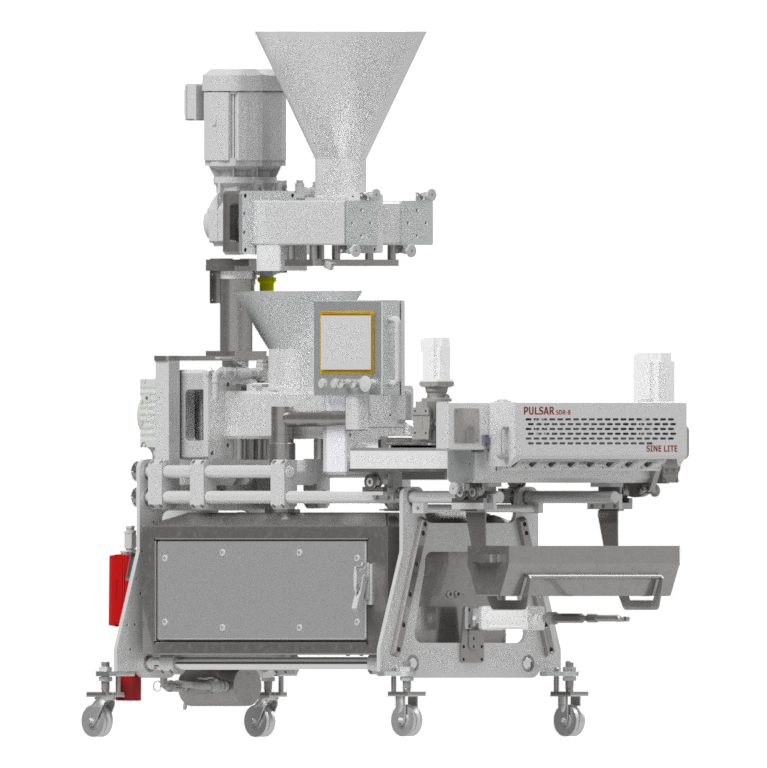

NOVA DOUGH DIVIDERS

SS-SDR-8 NOVA

+ Do-E6

Superior SS-SDR-8 NOVA + Do-E6 Single Servo Motor, Sine-Disk-Rotor stacked-up Metering pumps, the volumetric dough feed to each metering pump is pre-conditioned by in-line lane-port-channel manual trimming valve.

ORION DOUGH DIVIDERS

SS-SDR-6 + ORION

Do-E6

Single Servo Motor Sine-Disk-Rotor. Stacked-up Metering pumps the volume dough feed to each metering pump is pre-conditioned by an in-line lane-port-channel trimming manual valve.

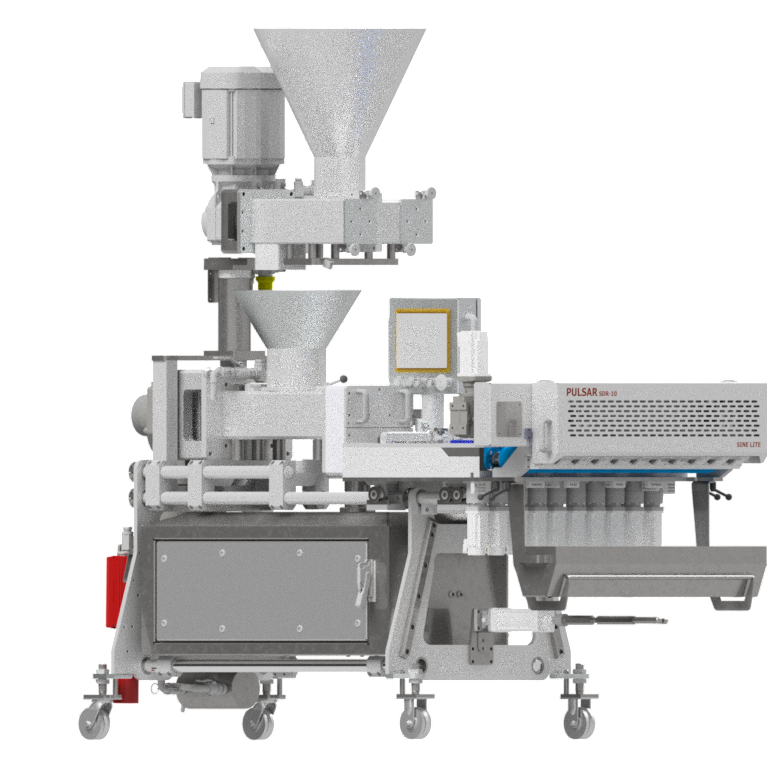

PULSAR DOUGH DIVIDERS

MS-HVR-8 PULSAR

Div. + Do-E6

The Impossible Ultimate MS-HVR-8 PULSAR Multi Servo Motor, Horizontal-Vane-Rotor + Flow-Meter monitoring and control in a close-loop in real-time Self-adjusting Volumetric-Mass/flow Controlled System, practically eliminates human intervention.

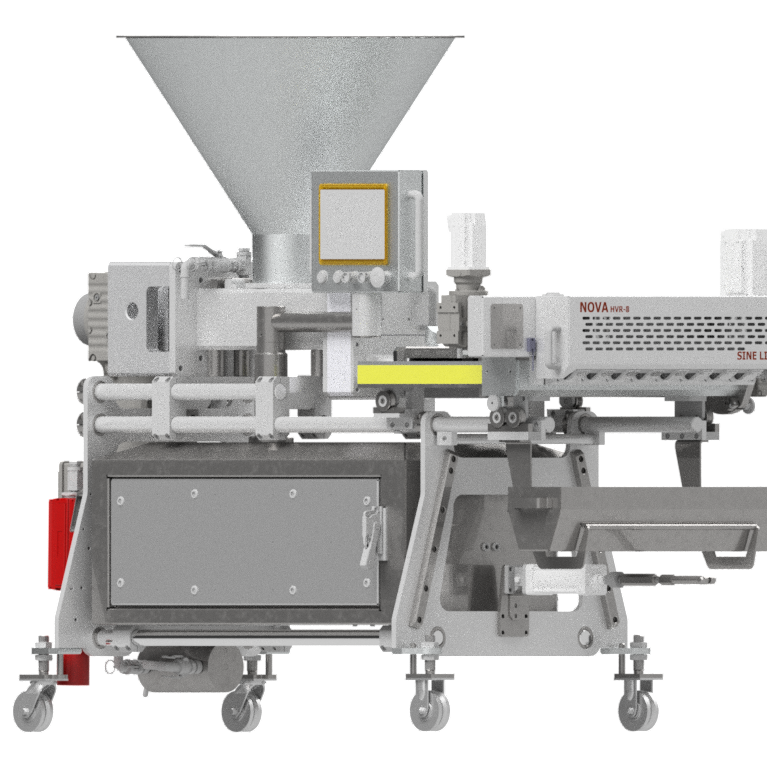

NOVA DOUGH DIVIDERS

SS-HVR-8 NOVA

Dividers

Superior SS-HVR-8 NOVA Single Servo Motor, Horizontal, Vane, Rotor stacked-up Metering pumps, the volumetric dough feed to each metering pump is pre-conditioned by in-line lane-port-channel manual trimming valve.

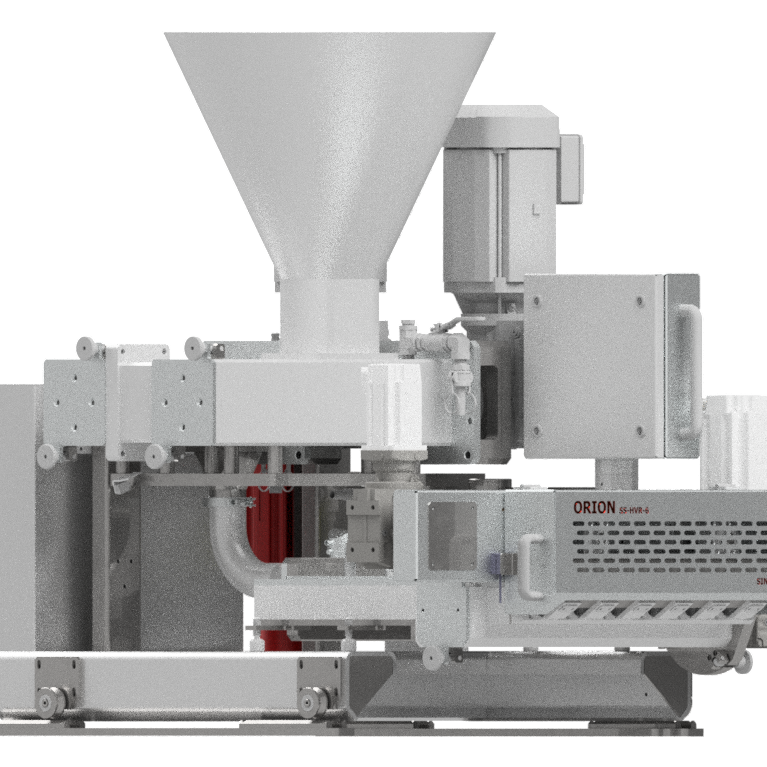

ORION DOUGH DIVIDERS

SS-HVR-4 ORION

+ Do-E6

Superior SS-HVR-4 + Do-E6 Single Servo Motor, Horizontal Vane-Rotor stacked-up Metering pumps the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve.

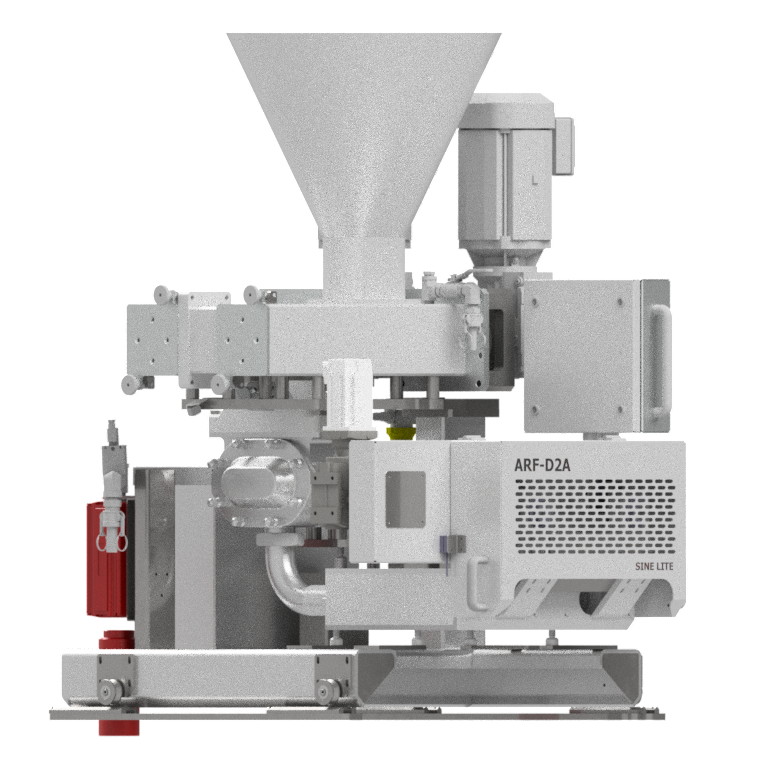

BREAD DOUGH DIVIDERS

ARF-D2A

Heavy-Duty Twin-Port Medium Volume, with built-in Do-E6 Emulsifier, Single-Auger feed pump, Positive displacement Metering-Pump, Servo-Cutting System Bread Divider, Ultra-Open design for easy cleaning and maintenance.

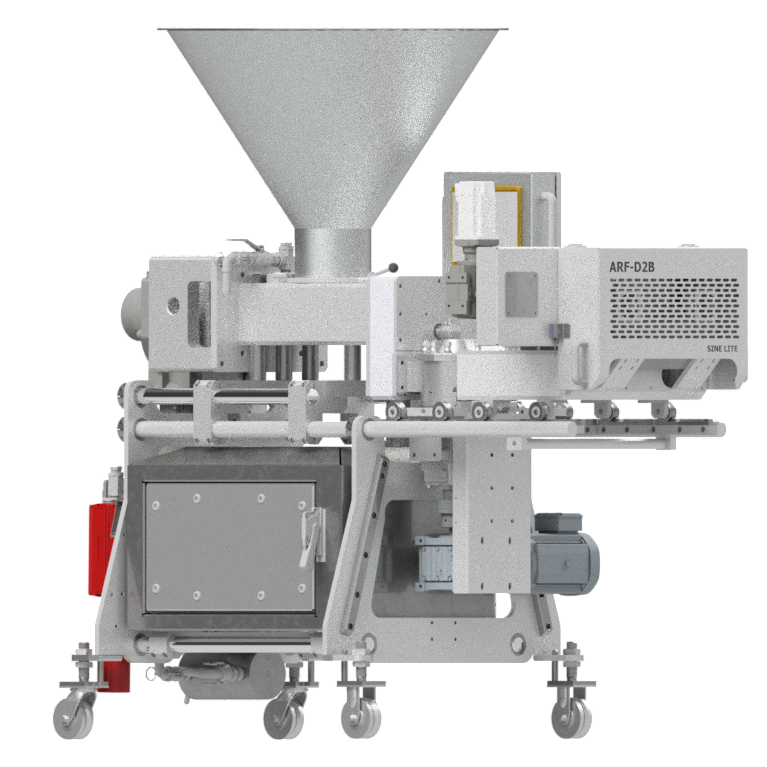

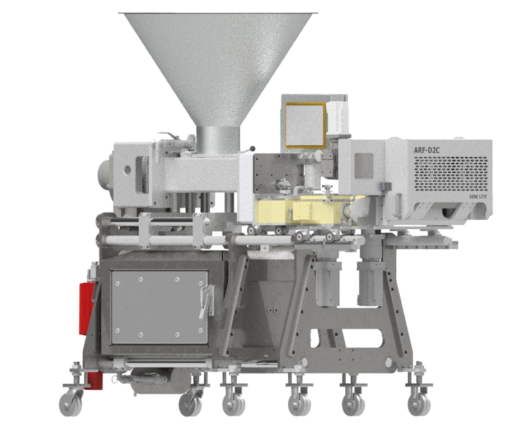

BREAD DOUGH DIVIDERS

ARF-D2B

Heavy-Duty Twin-Port High Volume Twin-Auger feed pump, Positive displacement Metering-Pump, Servo-Cutting System Bread Divider, Ultra-Open design for easy cleaning and maintenance.

BREAD DOUGH DIVIDERS

ARF-D2C SDR + FM

Heavy-Duty Twin-Port High Volume, Twin-Auger feed pump, introducing in-line FLOW-METER for Monitoring and Control per dividing-port Twin-SDR / HVR Metering-Pump, in a Close Loop control of Gearbox-Servo metering segment pump per port drive, to self-adjust the volumetric-mass flow to target value, in Real Time control dividing Technology, easy cleaning and maintenance.

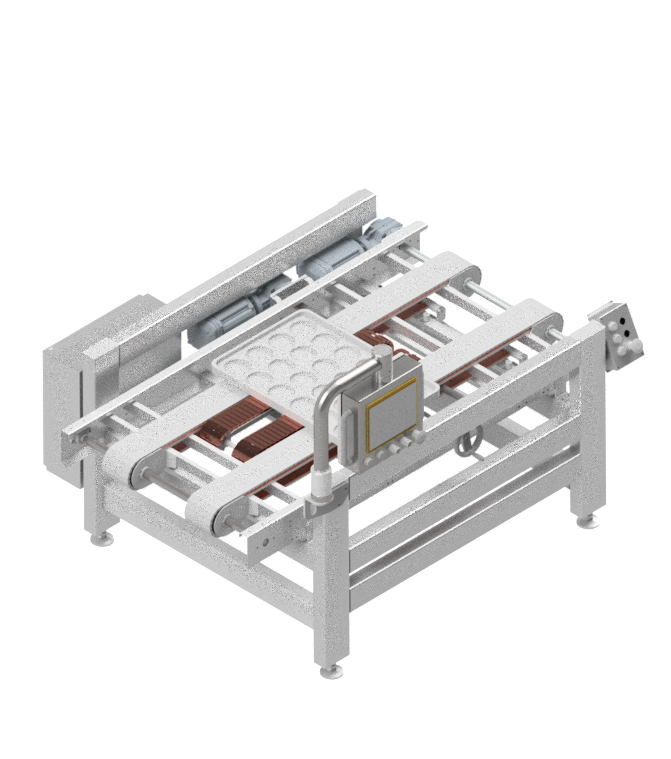

MAG PAN VIBRATOR

MAG-PAN-VIBRATOR 1O-RH

Superior In-Line Electronic Hot-Dog and Bun Pan Vibrator, settles Hot-Dog and Bun dough packets at the center of pan pockets, Ultra-Open design for easy cleaning and maintenance.

MAG PAN VIBRATOR

MAG-PAN-VIBRATOR 8-RH

Superior In-Line Electronic Hot-Dog and Bun Pan Vibrator, settles Hot-Dog and Bun dough packets at the center of pan pockets, Ultra-Open design for easy cleaning and maintenance.

MAG PAN VIBRATOR

MAG-PAN-VIBRATOR 6-RH

Superior In-Line Electronic Hot-Dog and Bun Pan Vibrator, settles Hot-Dog and Bun dough packets at the center of pan pockets, Ultra-Open design for easy cleaning and maintenance.

Still Have Some Questions Left?

Call us for a Free Consultation at

562-900-9999

We are happy to help you learn more about how our products can help your business.