Bakery Ultimate Systems

Setting the Ultimate standards to maximize your product quality and consistency with our new technology.

Our Industrial Bakery Equipment Systems Explained

We set the ultimate standards for bakery equipment highest speeds performance of industrial baking systems. Our goal is to supply you the latest innovation engineering designs and new technology to maximize the quality and consistency of your bakery products.

How our bakery equipment systems achieve this high standard.

Sine Lite’s GAME-CHANGING INNOVATIONS: US Patent Pending product dividing systems, Introducing the integration of in-line FLOW-METER per dividing port, on a close loop control of a gear-Servo drive metering segment-pump per port, to self-adjust the volumetric-mass flow on real-time control, to minimize human intervention and to achieve the ultimate consistent sustainable scaling accuracy.

What are the benefits to using our industrial bakery technology.

HIGHEST SPEEDS: Industry’s highest proven speeds up to and over 150 cuts per minute. (4″ Buns). Sine Lite is where industry game-changing innovations are born. Sine Lite manufactures the Baking Industries Premiere most advanced innovated Makeup Systems processes, ultimate accuracy and sustainability, industries proven highest speeds performance and sustainability of and over 150 cuts per minute.

FEATURING: The Ultimate MS-SDR PULSAR Div + Do-E6 + FLOW-METERING Control Dividing technology, offers Ultimate unmatched scaling accuracy, virtually no human interventions are required, designed for easy product change over.

Ultimate FLOW-METERING Control BUN DOUGH dividing technology

The Ultimate MS-SDR PULSAR Div + Do-E6

THE IMPOSSIBLE: Ultimate PULSAR Dividing Systems

THE IMPOSSIBLE: Ultimate MS-SDR-10 PULSAR Div + FM + Do-E6 Multi Servo Motor, Sine-Disk-Rotor Flow-Metering Control Metering Pump Dividing Systems, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve.

THE IMPOSSIBLE: Ultimate MS-HVR-10 PULSAR Div + FM + Do-E6 Multi Servo Motor, Horizontal-Vane-Rotor Flow Metering Control Metering Pump Dividing Systems, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve.

SUPERIOR HVR -METER Control BUN DOUGH dividing technology

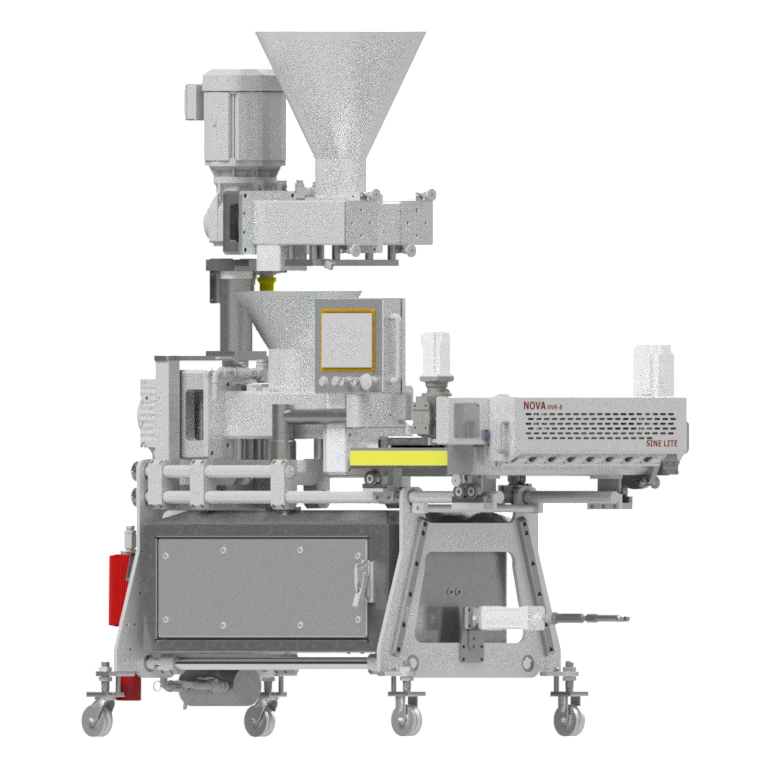

THE SUPERIOR SS-HVR-8 NOVA Div + Do-E6

THE SUPERIOR NOVA Dividing Systems

The SUPERIOR SS-HVR-8 NOVA Div + Do-E6, Single Servo Motor, Horizontal-Vane Rotor, Metering Pump Dividing Systems, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve.

The SUPERIOR SS-SDR-8 NOVA Div + Do-E6, Single Servo Motor, Sine-Disk Rotor, Metering Pump Systems, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve.

High speed bread dough divider

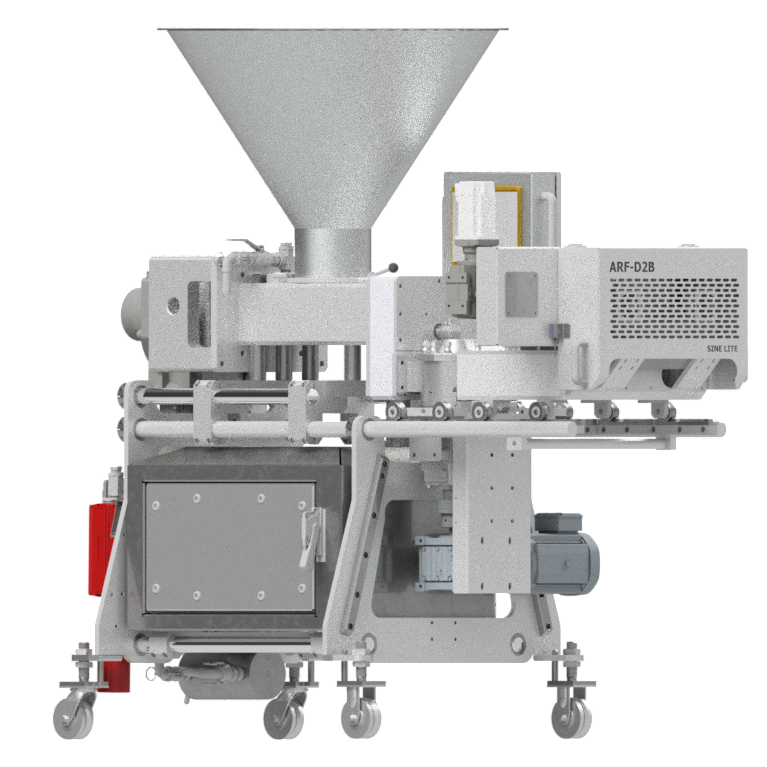

Series ARF-D2B Bread Divider.

THE SERIES: ARF-D2B Bread Divider multi-outlet single positive displacement metering pumps and our Servo -driven cutting system Bread Divider. Is designed to accommodate 1, 2-lanes of product.

SPEEDS: Up to and over 80 cycles per minute, at exact weights of or lower 1.0% deviation.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.

High speed bread dough divider

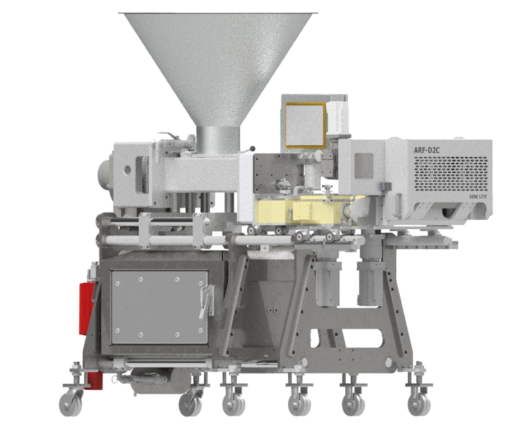

Series ARF-D2C SDR + FM Bread Divider.

THE SERIES: ARF-D2C SDR + FM Bread Divider multi-outlet Multiple positive displacement Servo Driven metering pumps and our Servo -driven cutting system Bread Divider. Is designed to accommodate 1, 2-lanes of product.

SPEEDS: Up to and over 90 cycles per minute, at exact weights of or lower 0.75% deviation.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.

High speed bread dough divider

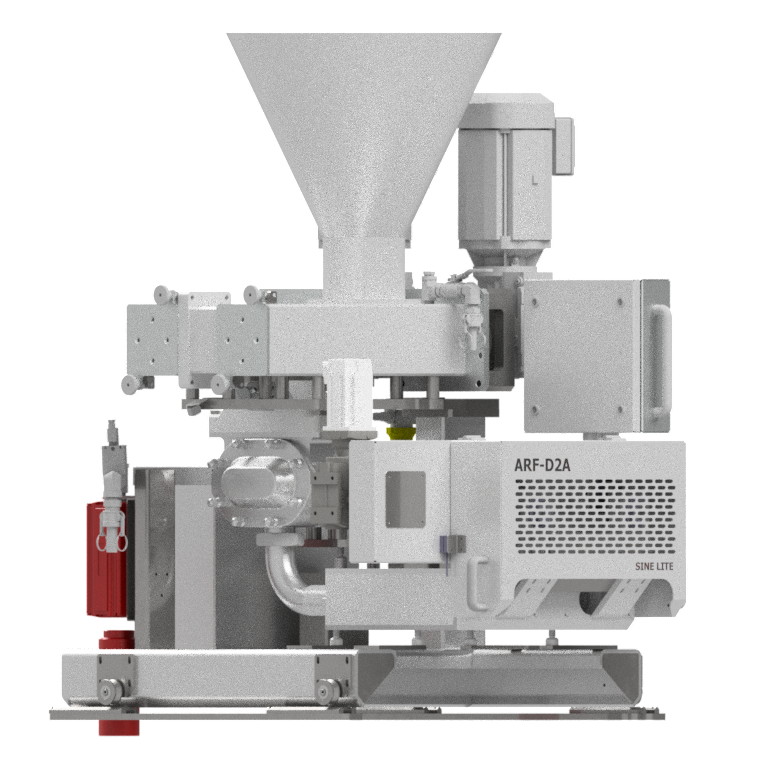

Series ARF-D2A + Do-E6 Bread Divider.

THE SERIES: ARF-D2A + Do-E6 Bread Divider multi-outlet single positive displacement metering pump and our Servo -driven cutting system Bread Divider. Is designed to accommodate 1, 2-lanes of product.

SPEEDS: Up to and over 75 cycles per minute, at exact weights of or lower 1.0% deviation.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.