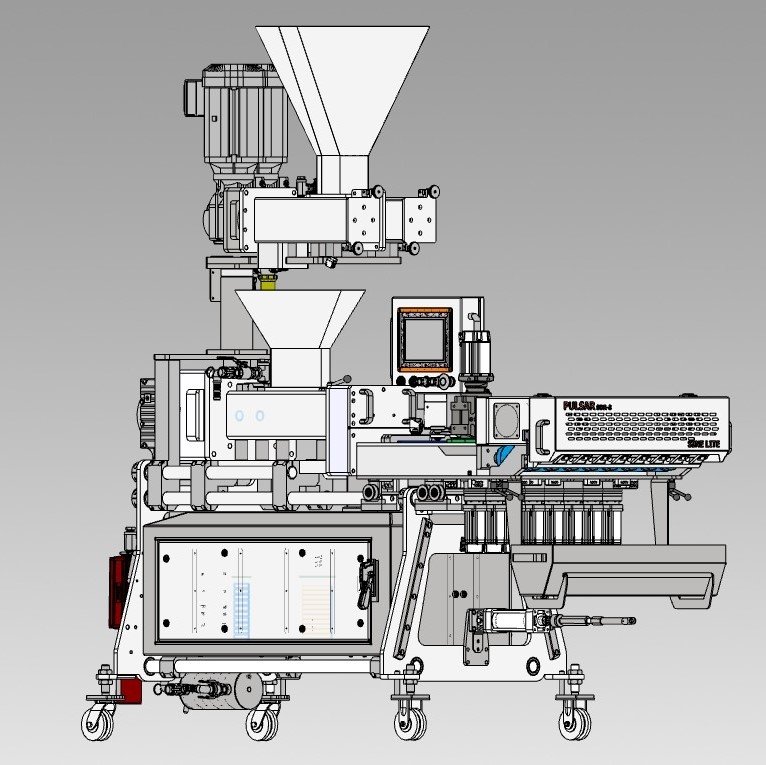

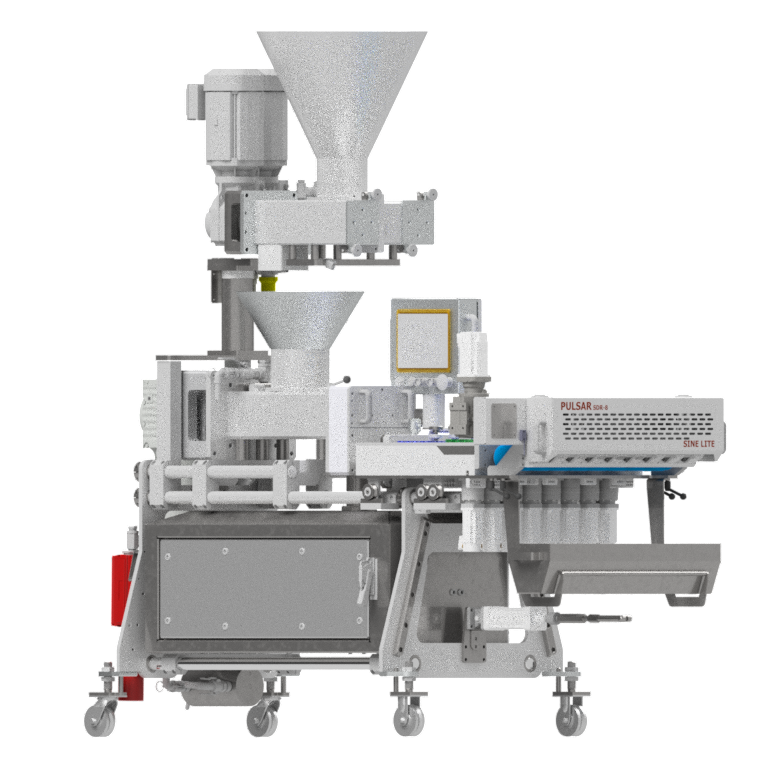

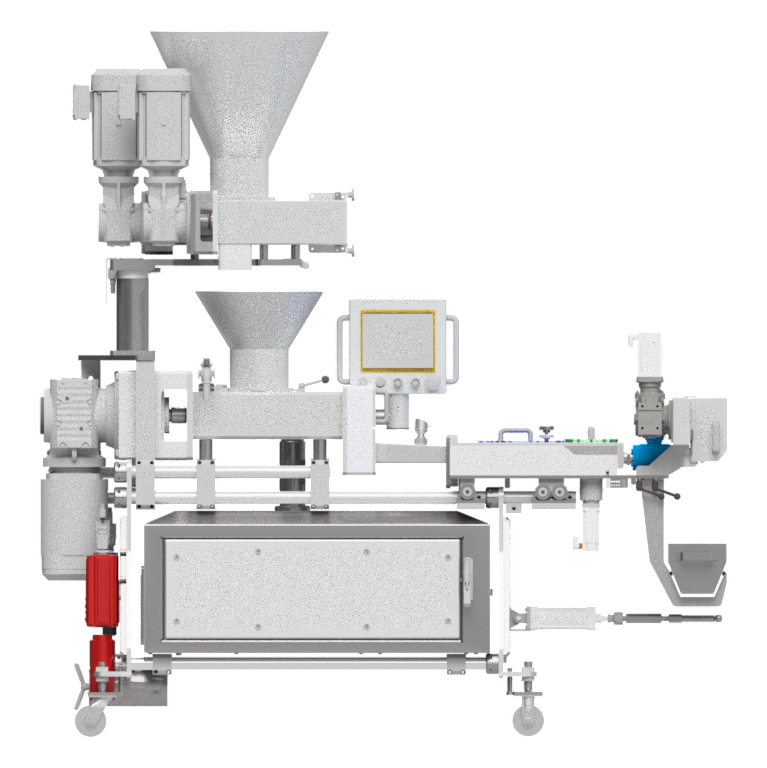

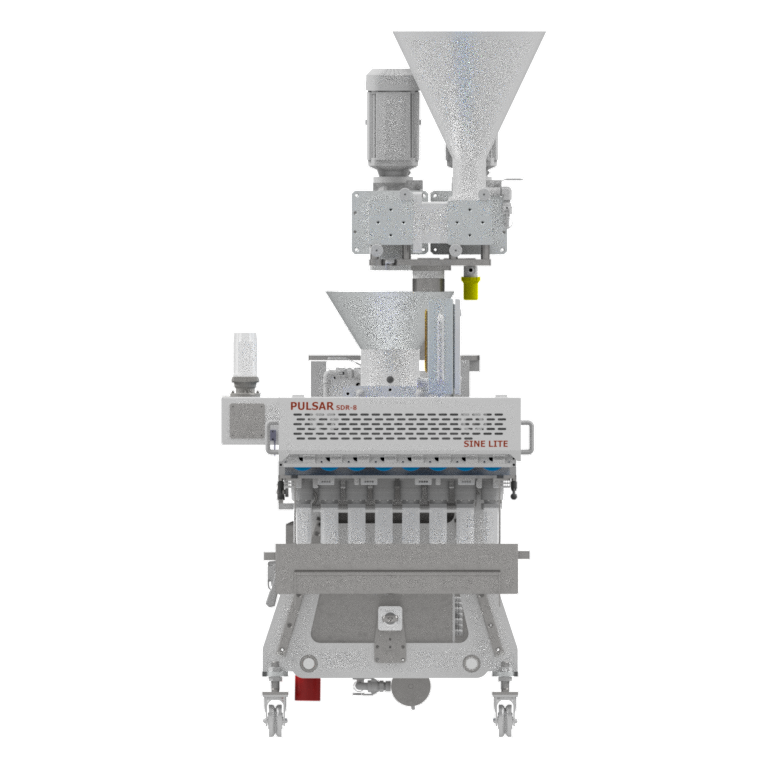

MS-SDR-8 PULSAR Div. + Do-E6

The Ultimate scaling accuracy divider, product quality and consistency with our new technology.

Ultimate Innovations ULTRA-OPEN Designs WASHDOWN Built to last

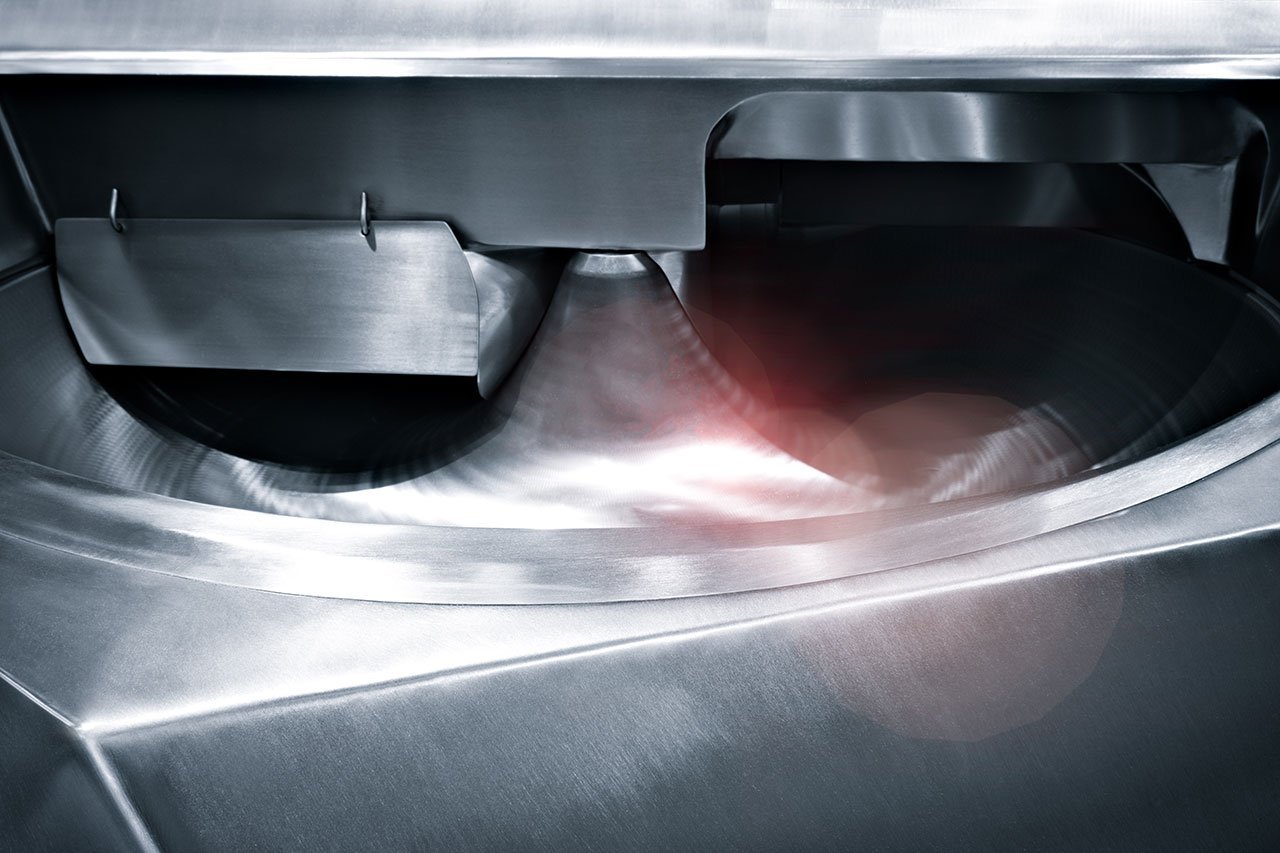

Ultimate PULSAR Bun Dough Divider has a positive displacement, large diameter, and low shear twin-auger pump system. This assures gentle handling of dough volumetric-mass / weight portions with a controlled constant low pressure dough feed to divider main manifold.

Specifications

Controls

Gear Motors

Construction

Controls

Controls: All Allen Bradley, PLC, 10″ color HMI, Servo Modules, VFD drives.

Recipe-Based Management System: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.

Gear Motors

Gear Motors: SEW integral IP 56 washdown Gear-Motors. Allen Bradley IP 56 washdown gear-Servo Motors.

Construction

Construction: All components, frames, fasteners, stainless-steel.

Scaling

Speeds

Scaling

Scaling Accuracy: SS-SDR-8 PULSAR + Do-E5 ultimate scaling accuracy is about or lower 0.5% deviation.

Speeds

Speeds: Up to and over 150/cycles/min. (4″ Buns), unmatched output, up to and over 72,000 pieces/hour.

For unmatched scaling accuracy, product consistency, integrate with Sine Lite’s Do-E5 dough Emulsifier.

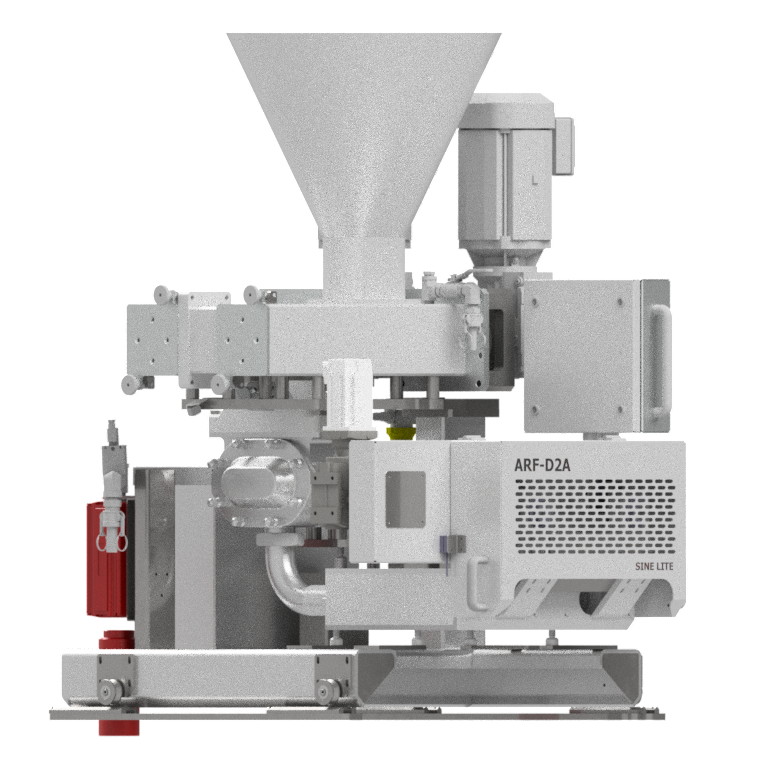

PULSAR Series MS-SDR-8 Divider + Do-E5

Multi-Servo SDR + Flow-Meter Managing System

THE IMPOSSIBLE: US Patent Pending, Ultimate MS-SDR-8 PULSAR + Do-E6 + In-line FLOW-METER / port self adjusting Volumetric-Mass/Weight flow monitoring in-real time Ultimate scaling control dividing technology, Multi Servo Motor, Sine-Disk-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance MS-SDR-8 PULSAR + Do-E5 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 150/cycles/min., unmatched output up to and over 72,000 pieces/hour, for unmatched scaling accuracy, quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

LOW SHEAR: Large diameter twin augers dough delivery system is unique for its gentle and consistent delivery of dough material to the divider main manifold and delivery to manifold port-channels.

THE IMPOSSIBLE: Multi outlet Ultimate MS-SDR-8 PULSAR + Do-E5 Multi Servo Bun Doug Divider, delivers the highest output in the industry (when integrated with our: Rounder, (IP) Tray proofer, Sheet-Rollers, Moulder, Panning Systems).

THE IMPOSSIBLE: Multi outlet Ultimate MS-SDR-8 PULSAR + Do-E5 Multi Servo driven Sine-Disk-Rotor metering pumps and our Servo -driven cutting system. Is designed to accommodate 6, 8, 10-lanes of product at up to and over 150/cycles/min., at exact weights of or lower 0.5% deviation.

THE IMPOSSIBLE: Ultimate SS-SDR-8 PULSAR + Do-E5 Multi-Servo drive metering pumps Bun Dough Dividers are designed for the highest efficient levels of production. The SDR (Sine-Disk-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.

TARGET VOLUMETRIC-MASS/WEIGHT: Port to port and cut to cut accuracy are easily achieved and maintained.

Models

- MS-SDR-6 PULSAR Divider

- MS-SDR-8 PULSAR Divider

- MS-SDR-10 PULSAR Divider

- MS-SDR-6 PULSAR Div + Do-E5

- MS-SDR-8 PULSAR Div + Do-E6

- MS-SDR-10 PULSAR Div + Do-E6

PULSAR Series SS-SDR-6 Div + Do-E5 Features

Sine Lite’s Do-E5″ and 6″ ID tunnels (Dough Conditioner) gives the Baker a controlled continuous consistent dough cellular-structure throughout the dividing-process time of each mix batch. In a Bakery Bun Line processing a single batches of dough mixes, as these batches are processed through the divider normally in about 15 to 17/min time, the dough mix starts to gas-up after 5/min. creating volumetric inconsistence in dough cellular structure.

The Sine Lite’s Do-E5-6″ ID tunnels (Do-Emulsifiers), pre-conditions (Emulsifies) the incoming gassed dough to an even dough cellular texture and delivers to the divider hopper.

PULSAR Dough Dividers can process a variable range of dough moisture absorption rates.

Absorptions rates from: 40% to 70% of water absorption.

PULSAR Dough Dividers eliminate the use of divider oil. The PULSAR Dough Divider does not require divider oil, saving thousands of Dollars annually while eliminating product air surface blisters and air pockets.

PULSAR Dough Dividers are designed for washdown all stainless-steel construction built as IP 56.

The PULSAR Bun Dough Dividers are designed for easy normal and deep cleaning (No tools needed) saving time and labor cost, and easy to pre-clean with the CIP feature program, the PULSAR Dividers are designed for easy access to divider main manifold cover doors, twin auger is easily removable, divider hoper is hinged to access augers twin-tunnels for cleaning.