Products

Setting the Ultimate standards to maximize quality and consistency with our new product technology.

Industrial Bakery Equipment Products

We set the ultimate standards for equipment’s highest speed performance for industrial baking systems. Our goal is to supply you with the latest innovative engineering designs and new technology to maximize the quality and consistency of your bakery products.

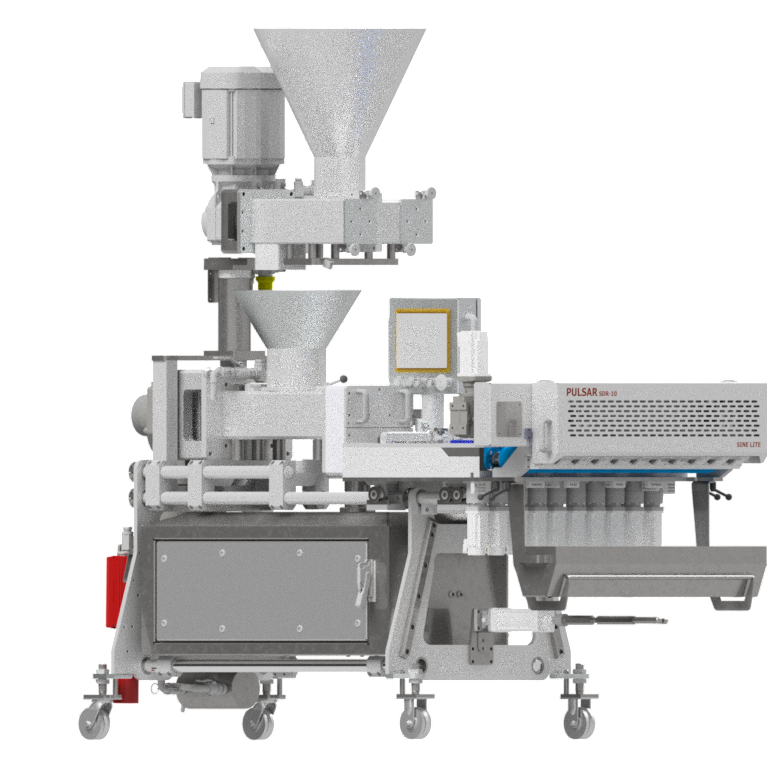

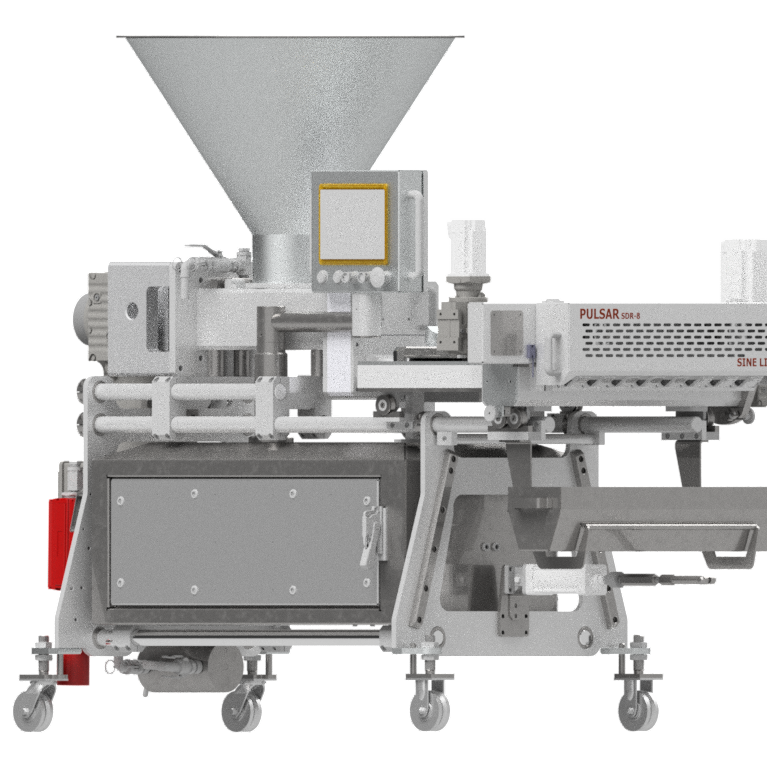

PULSAR MS-SDR Dividing Systems

MS-SDR-10 PULSAR DIV + do-e6

THE IMPOSSIBLE: Ultimate MS-SDR-10 PULSAR + Do-E6 Multi Servo Motor, Sine-Disk-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance MS-SDR PULSAR + Do-E6 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 150/cycles/min., unmatched output up to and over 90,000 pieces/hour, for unmatched scaling accuracy, and quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

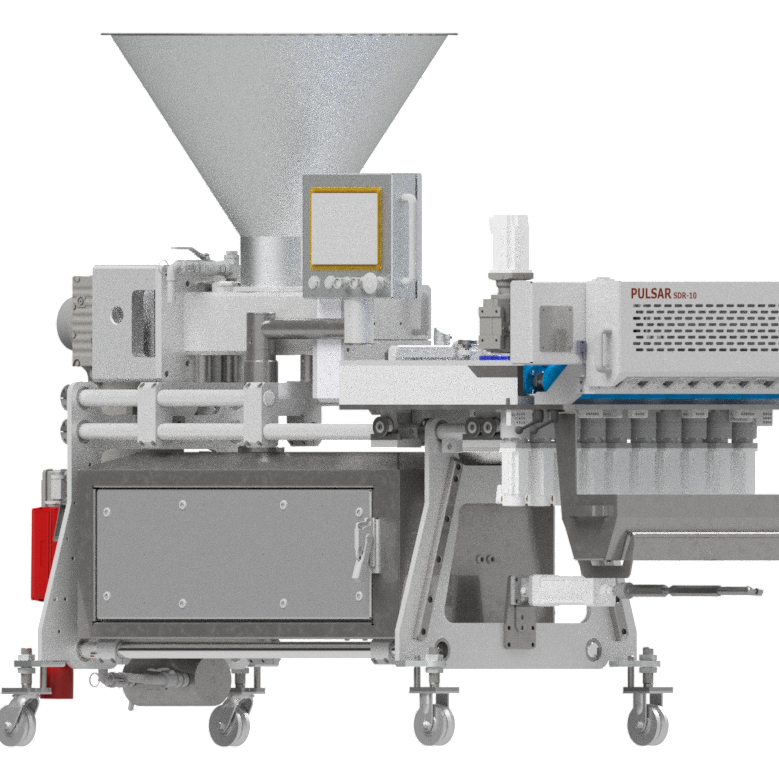

MS-SDR-10 PULSAR Divider

THE MULTI OUTLET: Ultimate MS-SDR-10 PULSAR Multi Servo driven Sine-Disk-Rotor metering pumps and our Servo-driven cutting system. Is designed to accommodate 6, 8, 10 lanes of product at up to and over 150/cycles/min., at exact weights of or lower 0.5% deviation.

THE IMPOSSIBLE: Ultimate MS-SDR-10 PULSAR Multi-Servo drive metering pumps Bun Dough Dividers are designed for the highest efficiency levels of production. The SDR (Sine-Disk-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from the divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

Target volumetric mass/weights: Port to port and cut to cut accuracy is easily achieved and maintained.

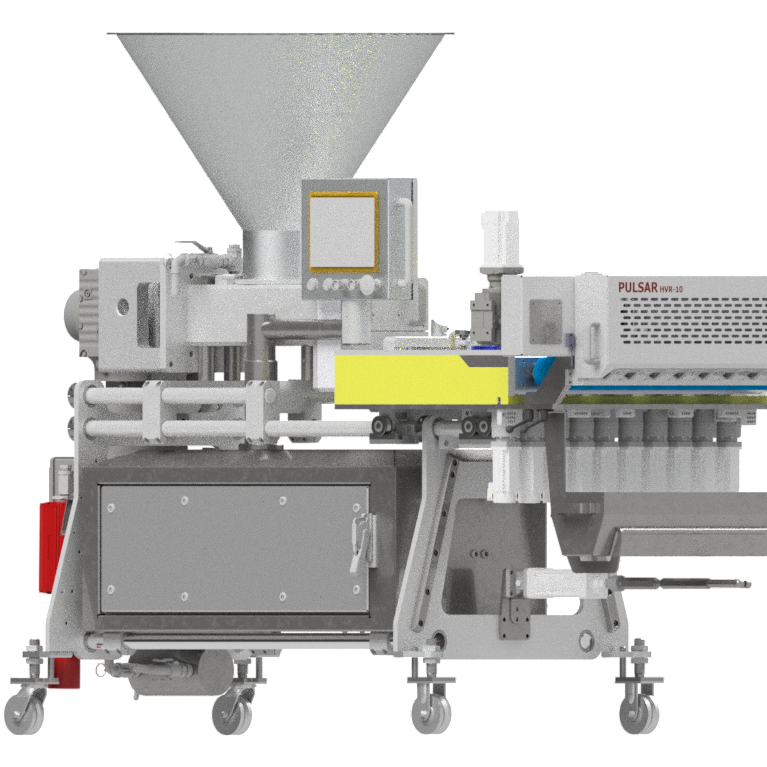

PULSAR MS-HVR Dividing Systems

MS-HVR-10 PULSAR DIV + dO-e6

THE IMPOSSIBLE: Ultimate MS-HVR-10 PULSAR + Do-E6 Multi Servo Motor, Sine-Disk-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance MS-HVR PULSAR + Do-E6 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 150/cycles/min., unmatched output up to and over 90,000 pieces/hour, for unmatched scaling accuracy, and quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

MS-HVR-10 PULSAR Divider

THE MULTI OUTLET: Ultimate MS-HVR-10 PULSAR Multi Servo driven Horizontal-Vane-Rotor metering pumps and our Servo-driven cutting system. Is designed to accommodate 6, 8, 10 lanes of product at up to and over 150/cycles/min., at exact weights of or lower 0.5% deviation.

THE IMPOSSIBLE: Ultimate MS-HVR-10 PULSAR Multi-Servo drive metering pumps Bun Dough Dividers are designed for the highest efficiency levels of production. The HVR (Horizontal-Vane-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from the divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

Target volumetric mass/weights: Port to port and cut to cut accuracy is easily achieved and maintained.

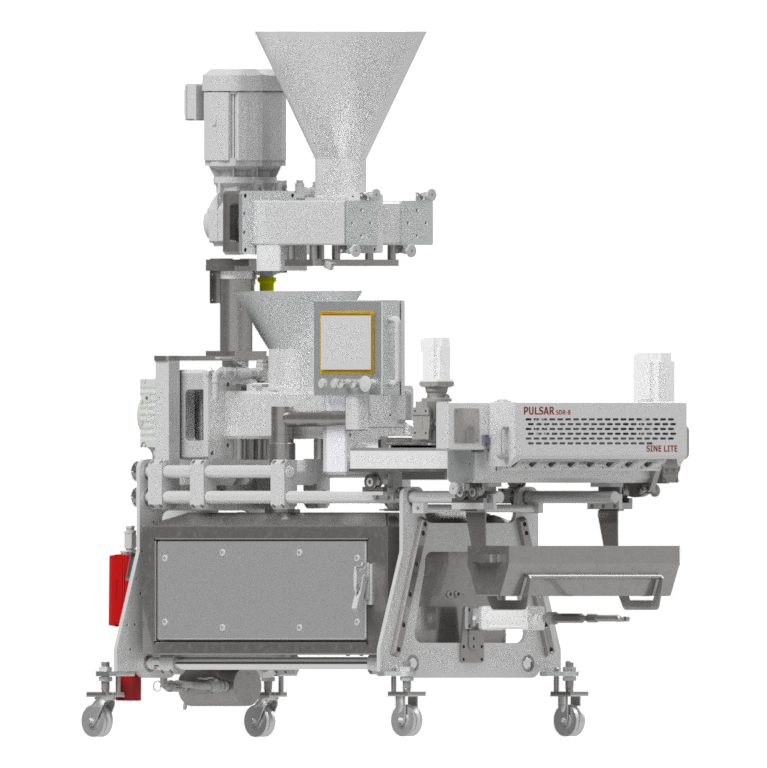

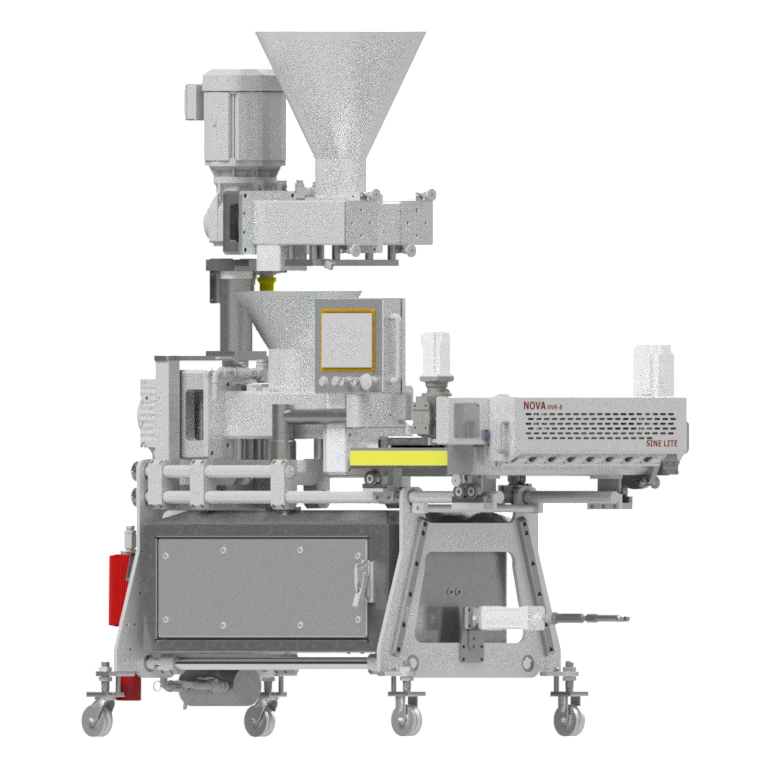

NOVA SS-SDR Dividing Systems

SS-SDR-8 NOVA DIV + dO-e6

THE SUPERIOR: Unmatched SS-SDR-8 NOVA + Do-E6 Single-Servo Motor, stacked up Sine-Disk-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance SS-SDR NOVA + Do-E6 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 150/cycles/min., unmatched output up to and over 72,000 pieces/hour, for unmatched scaling accuracy, and quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

SS-SDR-8 NOVA Divider

THE MULTI OUTLET: Unmatched SS-SDR-8 NOVA Single-Servo driven stacked up Sine-Disk-Rotor metering pumps and our Servo-driven cutting system. Is designed to accommodate 6, 8-lanes of product at up to and over 150/cycles/min., at exact weights of or lower 0.8% deviation.

THE SUPERIOR: Unmatched SS-SDR-8 NOVA Single-Servo drive stacked up metering pumps Bun Dough Dividers, are designed for the highest efficiency levels of production. The SDR (Sine-Disk-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from the divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

Target volumetric mass/weights: Port to port and cut to cut accuracy is easily achieved and maintained.

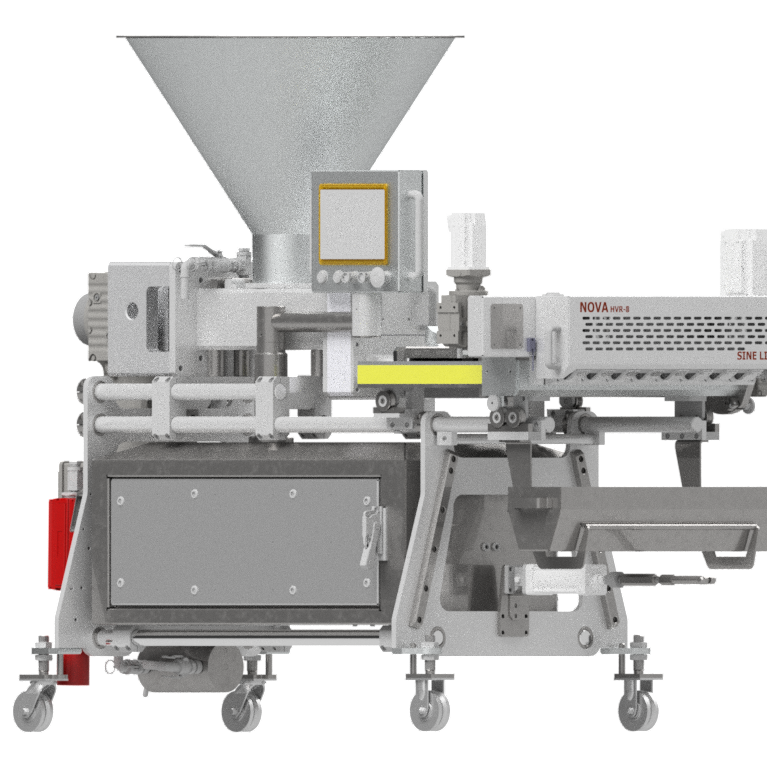

NOVA SS-HVR Dividing Systems

SS-HVR-8 NOVA DIV + dO-e6

THE SUPERIOR: US Patent Pending, Unmatched SS-HVR-8 NOVA + Do-E6 Single-Servo Motor, stacked up Horizontal-Vane-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance SS-HVR NOVA + Do-E6 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 150/cycles/min., unmatched output up to and over 72,000 pieces/hour, for unmatched scaling accuracy, and quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

SS-HVR-8 NOVA Divider

THE MULTI OUTLET: Unmatched SS-HVR-8 NOVA Single-Servo driven stacked up Horizontal-Vane-Rotor metering pumps and our Servo-driven cutting system. Is designed to accommodate 6, 8-lanes of product at up to and over 150/cycles/min., at exact weights of or lower 0.8% deviation.

THE SUPERIOR: Unmatched SS-HVR-8 NOVA Single-Servo drive stacked up metering pumps Bun Dough Dividers, are designed for the highest efficiency levels of production. The HVR (Horizontal-Vane-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from the divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

Target volumetric mass/weights: Port to port and cut to cut accuracy is easily achieved and maintained.

ORION SS-SDR Dividing Systems

SS-SDR-6 ORION DIV + dO-e6

THE SUPERIOR: Unmatched SS-SDR-6 ORION + Do-E6 Single-Servo Motor, stacked up Sine-Disk-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance SS-SDR ORION + Do-E6 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 140/cycles/min., unmatched output up to and over 50,400 pieces/hour, for unmatched scaling accuracy, and quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

SS-SDR-4 ORION Div + Do-E5

THE MULTI OUTLET: Unmatched SS-SDR-6 ORION Single-Servo driven stacked up Sine-Disk-Rotor metering pumps and our Servo-driven cutting system. Is designed to accommodate 4, 6-lanes of product at up to and over 140/cycles/min., at exact weights of or lower 0.8% deviation.

THE SUPERIOR: Unmatched SS-SDR-6 ORION Single-Servo drive stacked up metering pumps Bun Dough Dividers, are designed for the highest efficiency levels of production. The SDR (Sine-Disk-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from the divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

Target volumetric mass/weights: Port to port and cut to cut accuracy is easily achieved and maintained.

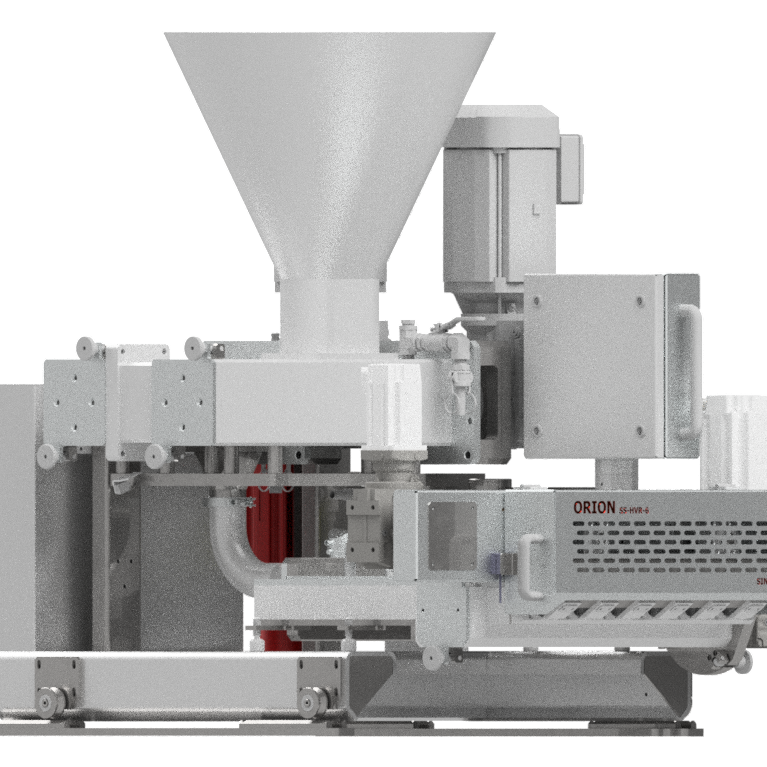

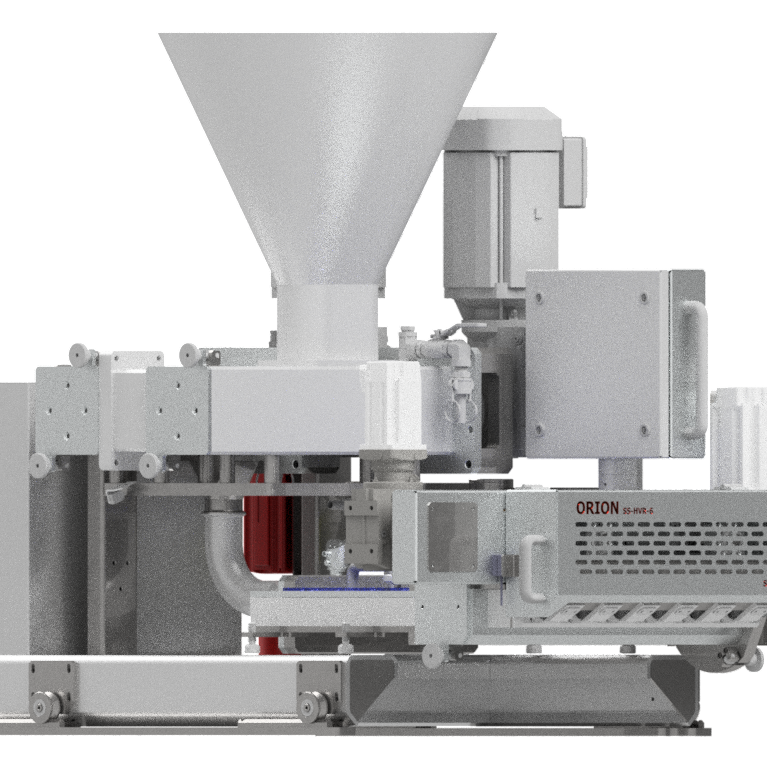

ORION SS-HVR Dividing Systems

SS-HVR-6 ORION DIV + dO-e6

THE SUPERIOR: Unmatched SS-HVR-6 ORION + Do-E6 Single-Servo Motor, stacked up Horizontal-Vane-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance SS-HVR ORION + Do-E6 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 140/cycles/min., unmatched output up to and over 50,400 pieces/hour, for unmatched scaling accuracy, and quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

SS-HVR-4 ORION Div + Do-E5

THE MULTI OUTLET: Unmatched SS-HVR-6 ORION Single-Servo driven stacked up Horizontal-Vane-Rotor metering pumps and our Servo-driven cutting system. Is designed to accommodate 4, 6-lanes of product at up to and over 140/cycles/min., at exact weights of or lower 0.8% deviation.

THE SUPERIOR: Unmatched SS-HVR-6 ORION Single-Servo drive stacked up metering pumps Bun Dough Dividers, are designed for the highest efficiency levels of production. The HVR (Horizontal-Vane-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from the divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

Target volumetric mass/weights: Port to port and cut to cut accuracy is easily achieved and maintained.

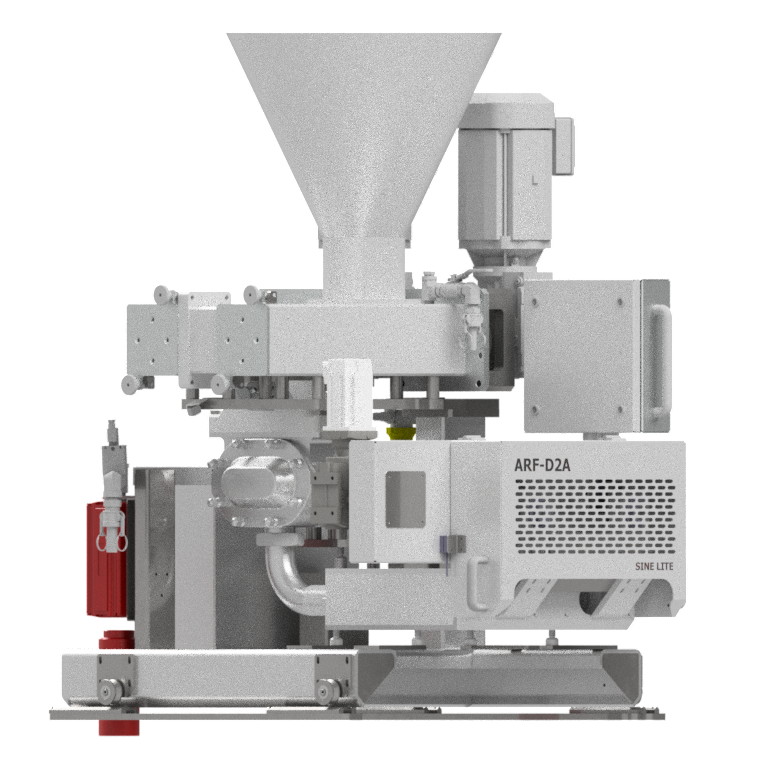

Bread ARF Dividing Systems

ARF-D2A + Do-E6 Bread Divider

THE SERIES: ARF-D2A + Do-E6 Bread Divider multi-outlet single positive displacement metering pump and our Servo -driven cutting system Bread Divider. Is designed to accommodate 1, 2-lanes of product.

THE SERIES: ARF-D2A 2-Port Bread Dough Divider

THE MULTI-OUTLET: ARF-D2A Single Metering Pump Bread Divider.

SPEEDS: The multi-outlet ARF-D2A 2-Port 70/Cycles/Min. at exact weight 1.0% scaling deviation.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.

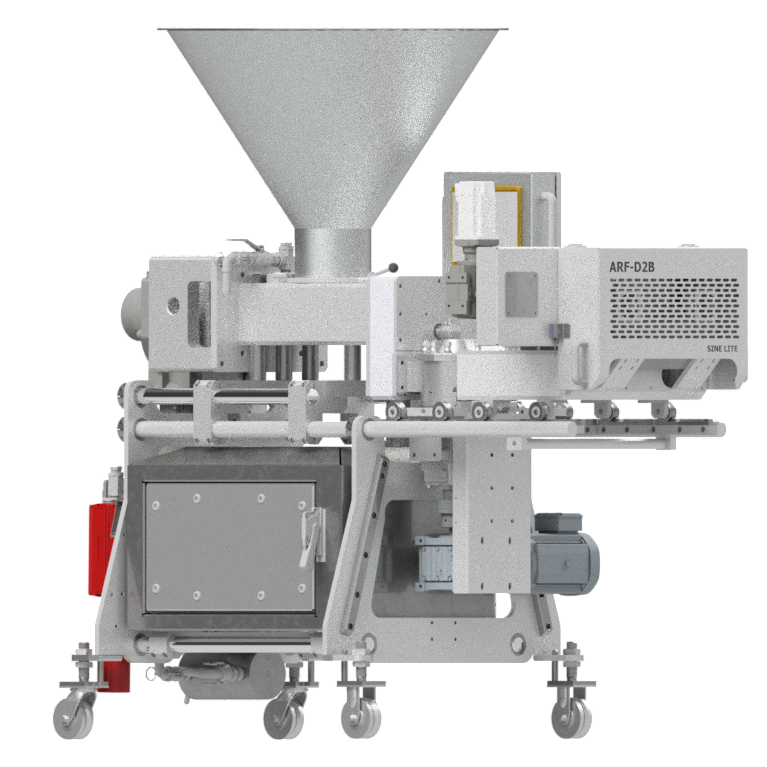

ARF-D2B Bread Divider

THE SERIES: ARF-D2B Bread Divider multi-outlet single positive displacement metering pump and our Servo -driven cutting system Bread Divider. Is designed to accommodate 1, 2-lanes of product.

THE SERIES: ARF-D2B 2-Port Bread Dough Divider

THE MULTI-OUTLET: ARF-D2B Single Metering Pump Bread Divider.

SPEEDS: The multi-outlet ARF-D2B 2-Port 100/Cycles/Min. at exact weight 1.0% scaling deviation.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.

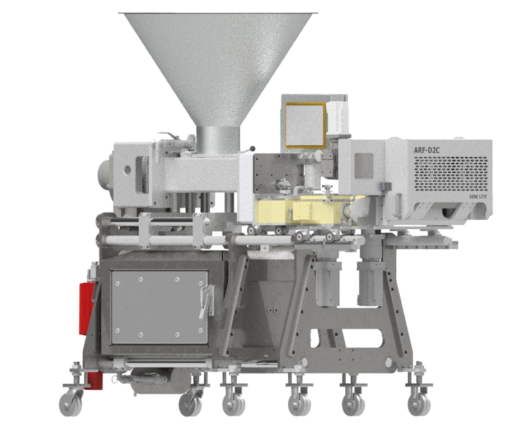

ARF-D2B -SDR + FM Bread Divider

THE SERIES: ARF-D2B-SDR + FM with Integration in-line FLOW-METERS/Port Bread Divider multi-outlet Twin positive displacement metering pumps Gear-Servo Driven and our Servo-driven cutting system Bread Divider. Is designed to accommodate 1, 2-lanes of product.

THE SERIES: ARF-D2B-SDR + FM, 2-Port Bread Dough Divider

THE MULTI-OUTLET: ARF-D2B-SDR Twin Metering Pumps Bread Divider.

SPEEDS: The multi-outlet ARF-D2B-SDR + FM, 2-Port 100/Cycles/Min. at exact weight 1.0% scaling deviation.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.

ARF-D2B-HVR + FM Bread Divider

THE SERIES: ARF-D2B-HVR + FM with Integration in-line FLOW METER Bread Divider multi-outlet single positive displacement metering pump and our Servo -driven cutting system Bread Divider. Is designed to accommodate 1, 2-lanes of product.

THE SERIES: ARF-D2B 2-Port Bread Dough Divider

THE MULTI-OUTLET: ARF-D2B Single Metering Pump Bread Divider.

SPEEDS: The multi-outlet ARF-D2B 2-Port 100/Cycles/Min. at exact weight 1.0% scaling deviation.

RECIPE-BASED MANAGEMENT SYSTEM: Product change over is as simple as selecting a recipe number, all Servo, VFD, drives recipe-set parameters are loaded into the running recipe number, with the option, of adjusting drives speed-parameters (Temporally for this run) if needed.