PULSAR MS-SDR Dividing Systems

The Impossible Ultimate scaling accuracy dividers, product quality consistency with our new technology.

Series PULSAR MS-SDR Bun Dividing Systems

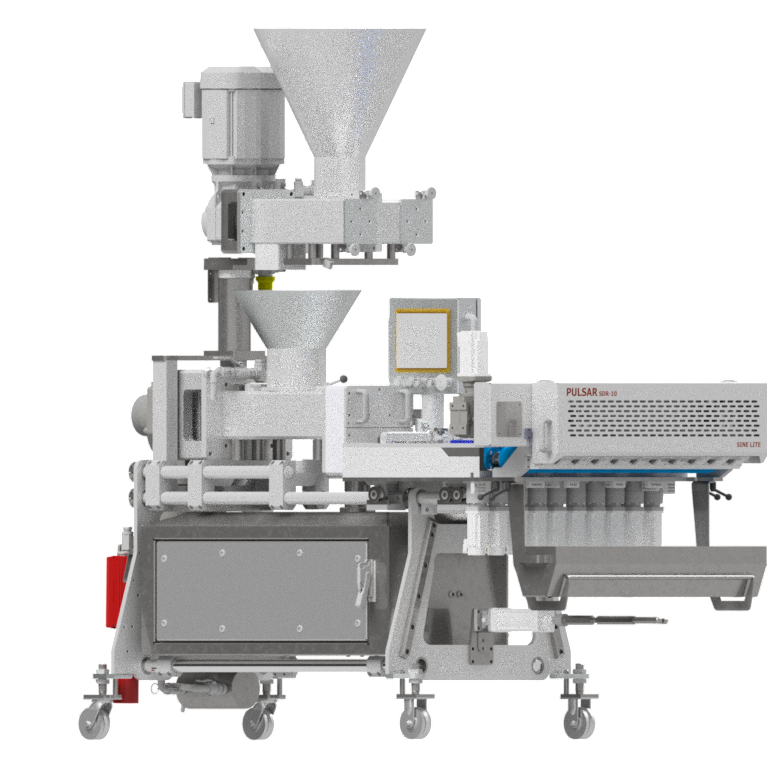

FEATURING: US Patent Pending, Ultimate MS-SDR PULSAR Div + Do-E6 + In-line FLOW-METER per port self adjusting Volumetric-Mass-Weight flow monitoring in-real time control dividing technology, offers unmatched scaling accuracy, virtually no human interventions are required, designed for easy product change over, Sine Lite’s Bun-Roll Dividing Systems, process a wide range of moist absorptions of soft or stiff dough mixes.

LOW MAINTENANCE COMPONENTS: Sine Lite’s PULSAR Dividing Systems are designed for simple operation, maintenance, and complete sanitation, easy access for deep cleaning, superior Engineering ULTRA-OPEN design of The Ultimate MS-SDR PULSAR Bun Dividers, are also designed as WASHDOWN by default, built as IP 56.

SPEEDS: Up to and over 150 cycles per minute(4″ Buns).p to and over 150

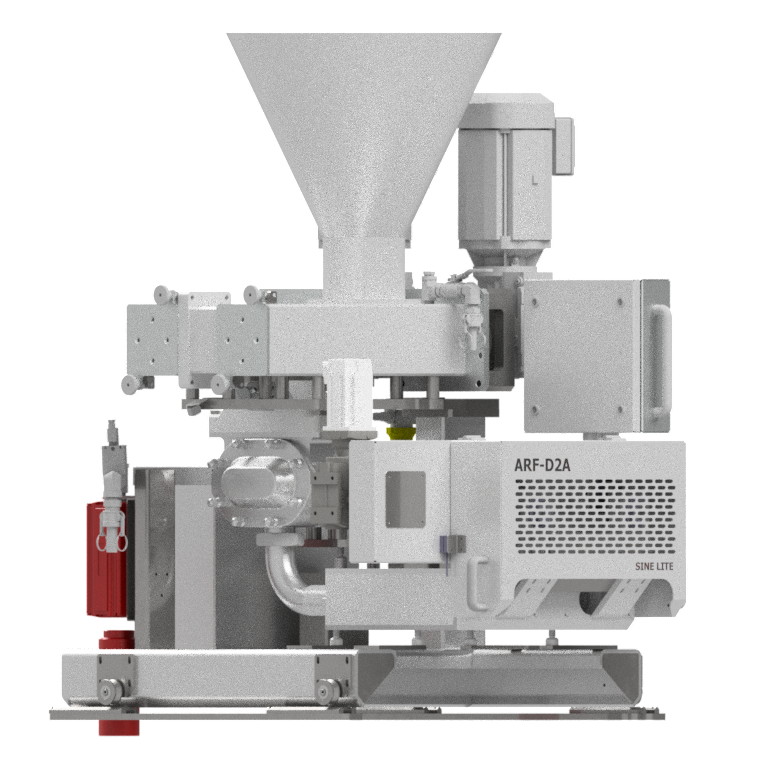

THE IMPOSSIBLE BUN DIVIDER: Ultimate MS-SDR PULSAR Multiple Gear-Servo Sine-Disk-Rotor, stacked-up metering-pump-Segments dough divider, cutting Knife Gear-Servo driven, (Optional) Sine Lite’s Swivel all Stainless Steel enclosure AB 10″ Color HMI.

DIVIDER DOUGH PUMP SYSTEM: Integrated with Variable pitch large 6″ Twin-Auger SEW Gear-Motor driven, Dough-Feed System.

ULTIMATE PULSAR DIVIDER CONTROLS: all Stainless Steel enclosures are build-in as an integral system, with Ethernet comm. with Main Makeup-Control PLC.

MS-SDR-10 PULSAR DIV + do-e6

THE IMPOSSIBLE: Ultimate MS-SDR-10 PULSAR + Do-E6 Multi Servo Motor, Sine-Disk-Rotor Metering pumps, the volume dough feed to each metering pump is pre-conditioned by in-line lane-port-channel trimming manual valve, Our high-performance MS-SDR PULSAR + Do-E6 divider is a direct replacement of outdated existing Bun Dough Dividers.

SPEEDS: Up to and over 150 cycles per minute, unmatched output up to and over 90,000 pieces/hour, for unmatched scaling accuracy, and quality consistency, available with optional Sine Lite’s Do-E5 Emulsifier (Dough conditioner).

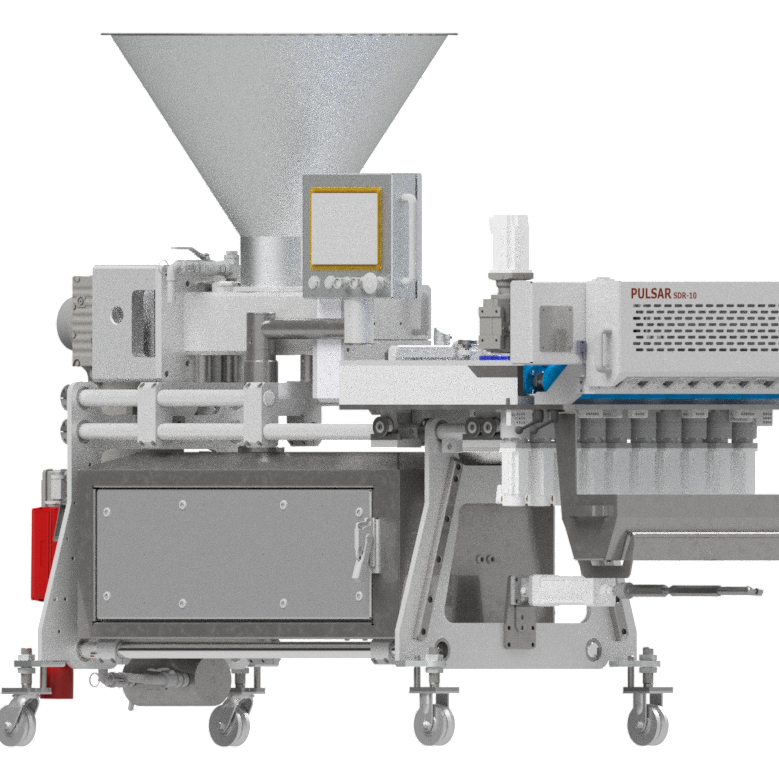

MS-SDR-10 PULSAR Divider

THE MULTI OUTLET: Ultimate MS-SDR-10 PULSAR Multi Servo driven Sine-Disk-Rotor metering pumps and our Servo-driven cutting system. Is designed to accommodate 6, 8, 10 lanes of product at up to and over 150 cycles per minute, at exact weights of or lower 0.5% deviation.

THE IMPOSSIBLE: Ultimate MS-SDR-10 PULSAR Multi-Servo drive metering pumps Bun Dough Dividers are designed for the highest efficiency levels of production. The SDR (Sine-Disk-Rotor) metering pumps can handle all types of baking dough–stiff or soft, designed to pre-condition the volumetric flow of product from the divider main manifold through the flow equalizer trimming manual valves per port-delivery channels.

Target volumetric mass-weights: Port to port and cut to cut accuracy is easily achieved and maintained.