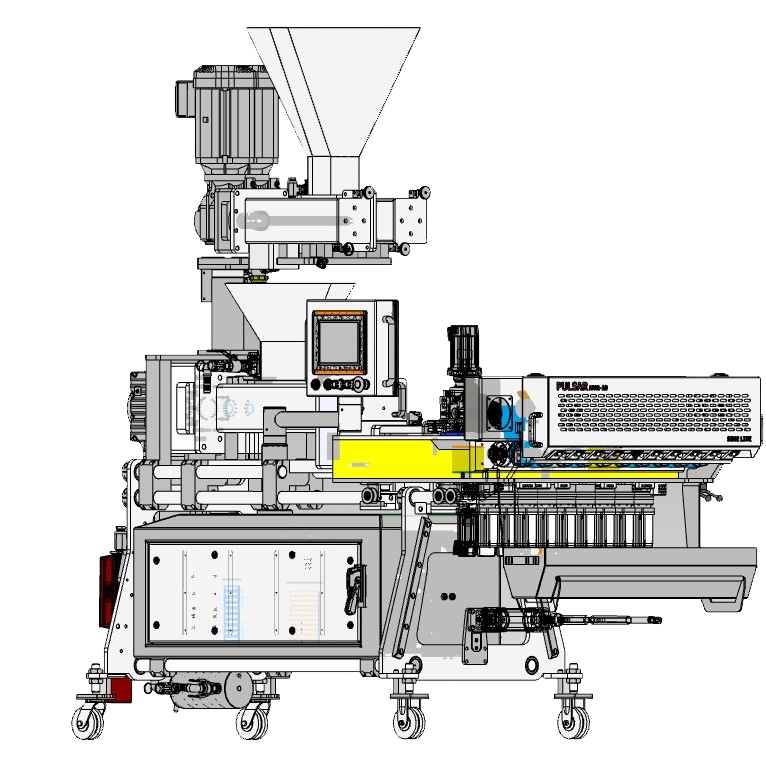

Ultimate High Speed Bun Make-Up Systems

Ultimate performance sets new standards for the baking industry’s high-speed bun makeup systems with our new superior design technology.

Modular Open Frame Design For Simplicity

The ultimate product quality for reduction of risk, optimizing production costs, and maximizing control for your bakery systems.

Produce consistent product quality in SINE LITE’S fully-integrated high-speed process environments for soft hamburger buns, assorted rolls, and hot dog buns. Setting the industry’s leading standard, our flexible soft bun and roll systems incorporate the proven accuracy of SINE LITE’s MS-SDR and MS-HVR extrusion dividers with the highest sanitary designs ensuring maximum product quality with simple operation. Produce up to 96,000 (4″-buns or rolls) per hour.

Bun Make-Up System Specifications

SPEEDS

The highest proven speeds, up to and over 150 cuts per minute (4″ Buns). Sine Lite is where the industry’s game-changing innovations are born. Sine lite manufactures the Baking Industries Premiere’s most advanced innovative Make-Up Systems processes, ultimate accuracy, and sustainability.

FEATURING

The Ultimate MS-SDR PULSAR Div + Do-E6 + FLOW-METER per dividing-port, in real-time Monitoring in a close loop Control of gear-Servo metering segment-pump per port drive, to self-adjust the volumetric-mass to target flow rate value, in real-time control dividing technology, offers Ultimate unmatched scaling accuracy, virtually no human interventions are required, designed for effortless product change over.

ULTIMATE HIGH-SPEED BUN MAKE-UP SYSTEMS

Process a wide range of moisture absorptions of soft or stiff dough mixes. Sine Lite’s Ultimate High-Speed Bun Make-Up Systems are second to none in the Baking Industry.

ROLL-BUN MAKE-UP SYSTEMS

Introduces six series of Roll-Buns Make-Up Systems.

INNOVATION

US Patent Pending dividing systems, Introducing the integration of in-line FLOW-METER per dividing port, in a close loop control of a gear-Servo metering segment-pump per port drive, to self-adjust the volumetric-mass to target flow value, in real-time control Dividing Technology, to minimize human intervention and to achieve the ultimate consistent, sustainable scaling accuracy.

Ultra-Open Design Features

THE IMPOSSIBLE DIVIDERS

US Patent Pending, Ultimate MS-SDR/HVR Multi Gear-Servo Sine-Disk-Rotor / Horizontal-Vane-Rotor metering-pump-Segment + Flow-Metering volumetric-mass flow Monitoring and Control, in a close-loop, in a real-time, self-adjusting monitoring and Control System, dough dividers, cutting Knife Gear-Servo drive, (Optional) Sine Lite’s all Stainless Steel swivel enclosure, with A/B 10″ Color HMI.

DIVIDER DOUGH PUMP SYSTEM

Integrated with variable pitch large 6″ Twin-Auger SEW Gear-Motor driven, Dough-Feed System.

PULSAR DIVIDER CONTROLS

All Stainless Steel enclosures are build-in as an integral system with Ethernet communications with central Make-Up Control PLC.

EMULSIFIER

Do-E6″ ID Tunnels (Dough Emulsifier) (Dough Conditioner), integrated with a 6″ ID Auger, as a dough-pump system, and a 6″ double blade Emulsifier, each driven by a SEW integral Gear-Motor.

ROUNDER BED

Rounder-LONG-Bed, Frames all Stainless Steel construction, with self-rounder-belt tracking “V” roller.

ROUNDER BARS

SD (Grooved-Dimples rounding surfaces) UHMW LONG-Rounder bar.

TRANSFER ROLLER

Rounder Belt dough Transfer-Roller, variable speed AC VFD drive.

ZIG-ZAG-FLOUR DUST COLLECTOR

Vibrating screening system to remove crams off the exes-dusting flour sliding down from Zig-Zag board.

TRAY-PROOFER TOWER

Main drive Gear-Servo Driven.

ZIG-ZAG Rotary-GATE

Zig-Zag UHMW Rotary-Gate Gear-Servo drive, Construction.

INTERMEDIATE PROOFER (IP)

Tray Proofer Intermediate (IP) frames are all bolt-on, access doors, all Stainless Steel construction.

SHEET-MOULDER PANNING FRAMES

Sheet-Rollers-Drive-Boxes, Moulder-Belt, Panning, support frames, all Stainless Steel construction.

SHEET-ROLLERS ROTARY-GATES

Stainless Steel-guided UHMW-Roller-Rotary-Gates, are slide-adjustable side-to-side, Gear-Servo driven.

MOULDER BELT

Moulder Belt Frame, Belt Drive-Idler-Rollers, Moulder Belt Under-Catch Flour-Dust collector Pans, all Stainless Steel construction.

HOT-DOG PRESSURE-BOARDS

Hot-Dog Pressure UHMW-boards, height-adjustment UHMW-hinges.

HOT-DOG ROTARY-GATE

Hot-Dog Rotary-Gate. UHMW-Gate Gear-Servo Driven, all Stainless Steel construction.

MAG-PAN-Vibrator

New Hot-Dog, Bun Pans, Electronic Bun-pan Vibrators, 4, 6, 8, 10 Systems